Hub and SPOKE Model

On-the-ground solutions delivery

The core structure for delivery is a "hub and SPOKE" model, with a single centre servicing one or more SPOKEs in neighbouring locations.

We aim to create a comprehensive suite of services - delivered through specialised Centres of Excellence for Sustainable Cooling and Cold-Chains (i.e. Rwanda, Africa and Haryana, India) and regional SPOKEs - to accelerate the uptake of sustainable cooling and cold-chain in the Global South. Uniquely, it is designed to develop and transition to a self-financing, growth business model, thereby delivering long-term and sustained impact, along with the immediate wins.

Centres of Excellence

Africa

ACES is housed on a five hectare campus with an adjacent 200 hectare farm in Kigali, Rwanda. Collaborative research, new equipment testing, and the development of knowledge training programmes and robust business models takes place here.

India

To establish the CoE, the state government has allotted ca. 15 acres (6 ha.) of land within the premises of the Directorate of Horticulture (DoH) at Panchkula, Haryana. Test laboratories, demonstration facilities, a community cooling hub, training centre and incubation hub will all be available.

SPOKEs

SPOKEs showcase how solutions can be deployed in practical, real-world applications and provide on-the-ground training, capacity building, and support for farmers and their communities to;

- design sustainable community cooling and cold-chain solutions,

- develop financeable business models, through to the day-to-day operations and Post-harvest Management,

- develop a network of skilled engineers coming from the Centre of Excellence and SPOKE, to support equipment installation and maintenance.

Reference SPOKE - Kenya

The first SPecialised Outreach and Knowledge Establishment (SPOKE) is in Kenya. Kenya is the reference SPOKE through which we are designing the SPOKE programme, building the delivery team and developing the toolkits for our reference and replicate model.

The SPOKE team provides the essential enabling mechanisms, tools, technology selection, business model, governance and operational systems, and the targeted training necessary to support community leaders and the wider community. This will help establish a grassroots, community cold-chain ecosystem and integrate cold-chain into their operations.

The SPOKE programme works in three phases, taking a journey from initial community partnership scoping in Phase 0, then through Phase 1 establishing the engagement framework and support ecosystem, and finally in Phase 2 implementing the Try Before You Buy model on-the-ground and proving practical viability

As an example of the programme’s success, the Lari cooperative, our first community SPOKE in Kenya, has been able to aggregate its produce through its cold-chain and market its top-quality produce to higher-end markets.

They earn, on average, over 50% higher returns for their produce than previously.

Essential reading

ACES graduate hopes to become Rwanda's leading supplier of rabbit meat

17th Nov 2025

Albertine Uwajeneza, a cold chain technician and rabbit farmer from Muhanga, Rwanda, is hoping to use cold chain technology to supply rabbit meat to upmarket bars, restaurants and supermarkets across the country.

Optimising the Vaccine Cold-Chain for Resilient Immunisation in Africa

14th Nov 2025

We are helping to pioneer climate-smart and data-driven approaches to optimise vaccine cold-chain performance and strengthen One Health resilience.

Inspired by the CCN’s Cold-Chain for Global Health Programme

12th Nov 2025

By combining observation, research, and interdisciplinary collaboration, Cold-Chain for Global Health trainees are forging a bold path forward, reflecting and replicating newly learned innovative models to develop actionable, scalable systems in their local contexts.

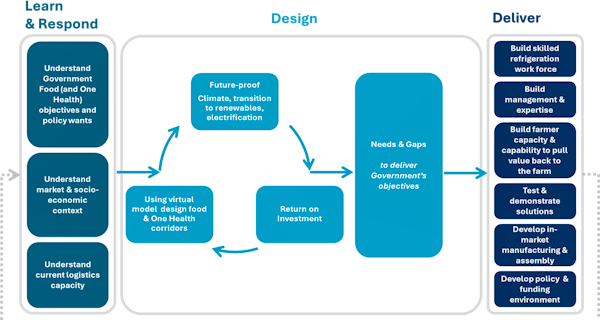

Sustainable Cold-Chain For The Global South 2025

3rd Nov 2025

Investigating how we have set out to holistically understand and cover all bases, from designing food and planning health corridors, future energy strategies, and climate risk mitigations, to pulling value back to farming communities, training engineers and technicians, and understanding overall value.

"Born in Rwanda but pan-Africa in Vision": 2026 - Putting words into practice through The ACES SPOKE programme.

31st Oct 2025

Our overarching objective is to combine training, support and technology demonstration to accelerate the deployment of sustainable, resilient and equitable cold-chains across the Global South.

A Cool World: What to expect and what I am excited about!

17th Oct 2025

Dr. Tim Fox discusses what he's most looking forward to at "A Cool World: Sustainable Cold-Chain for the Global South" conference.

Equitable and inclusive cold-chains – putting the vision into practice

25th Sep 2025

The key question we have laid down at CCN is: "How do we unlock Africa’s agricultural potential to feed itself and the world whilst also economically empowering smallholder farmers and making them climate-resilient … all without using diesel?"

Cooling isn’t just nice to have; it is central to a modern civilisation

19th Aug 2025

Celebrating cooling through the Festival of Cooling. Without reliable ways of transporting food in a cooled environment, food arrives at its destination spoiled, sales are lost, and the livelihoods of farmers, fishers and other producers suffer. These stories are repeated across Rwanda and across Sub-Saharan Africa time and time again.